Oil & Gas Training

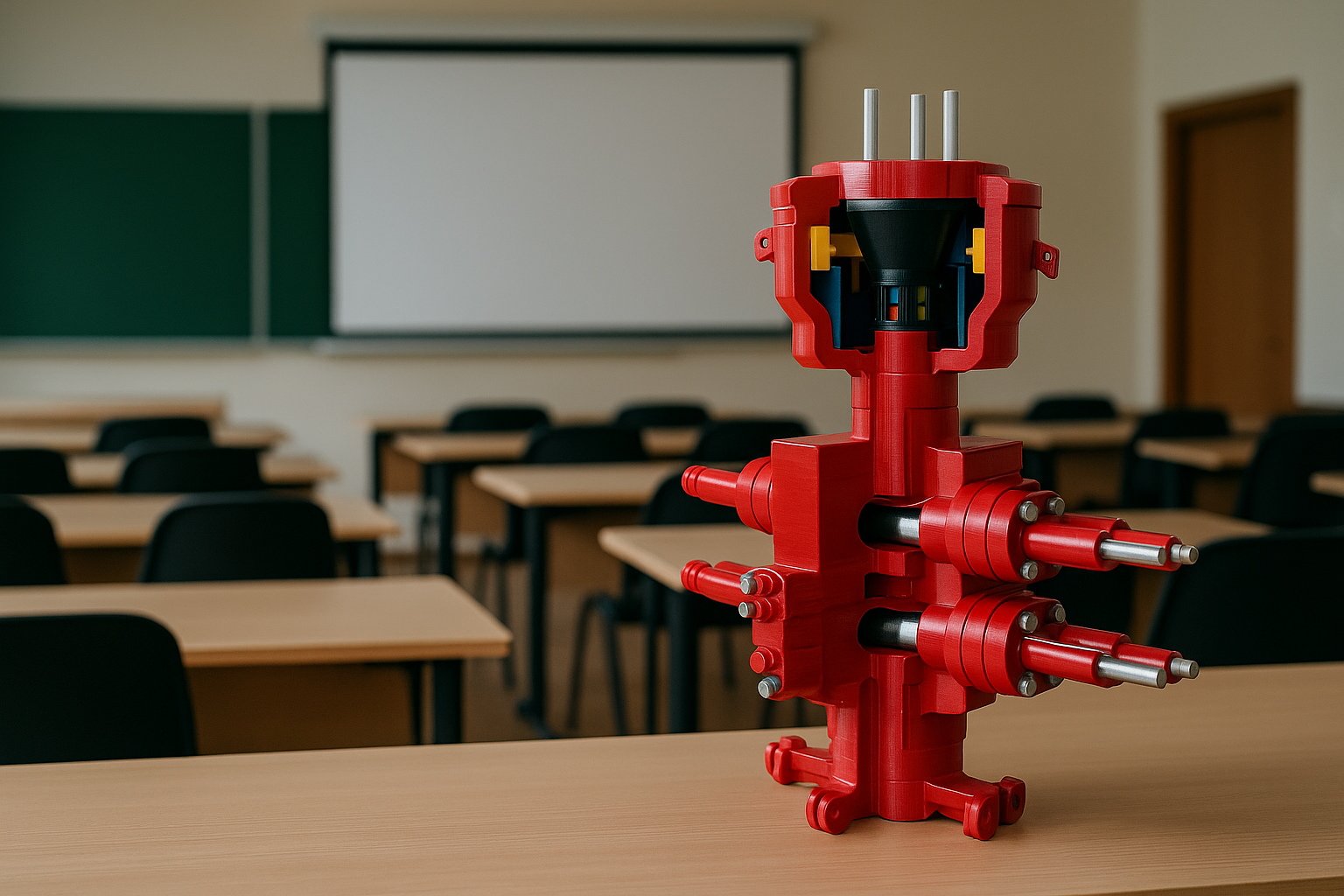

Boosting Safety & Precision with Custom 3D-Printed BOP Simulators

The Challenge

Traditional training methods for Blowout Preventers (BOPs) often relied on 2D diagrams or costly industrial equipment, leading to gaps in understanding critical safety mechanisms.

Our Solution

We designed and 3D-printed scaled, high-precision BOP models used in simulated training environments. These tactile learning tools help instructors demonstrate sequences, failure modes, and safety procedures more effectively.

- ✔️ Detailed 3D modeling of complex components

- ✔️ Durable SLA & FDM-printed models

- ✔️ Used in over 12 training centers across Latin America

The Results

The implementation of our BOP training models led to a 40% improvement in learner retention and reduced training time by over 25%.

See It in Action

Hands-on training with 3D-printed BOP models at training centers.

Related Projects

3D Printed Training Models

High-precision 3D printed models used in educational settings.

Interactive Simulations

Simulations designed to mimic real-world scenarios.

Float Valve

Demonstrates the function of float valves in fluid systems, primarily used in training sessions to illustrate valve mechanics.

Annular Blowout Preventer (BOP)

A critical safety device used in drilling operations to control well pressure. It features a flexible, elastomeric sealing element that can form a tight seal around the drill pipe or the annular space. Its primary function is to contain hazardous pressures and prevent uncontrolled fluid flow.

Interactive Simulations

Simulations designed to replicate real-world training scenarios effectively.

Float Valve

A mechanical device used in fluid systems to control flow based on the fluid level. It operates by utilizing a buoyant element (the float) that rises or falls with the fluid level, activating the valve mechanism.